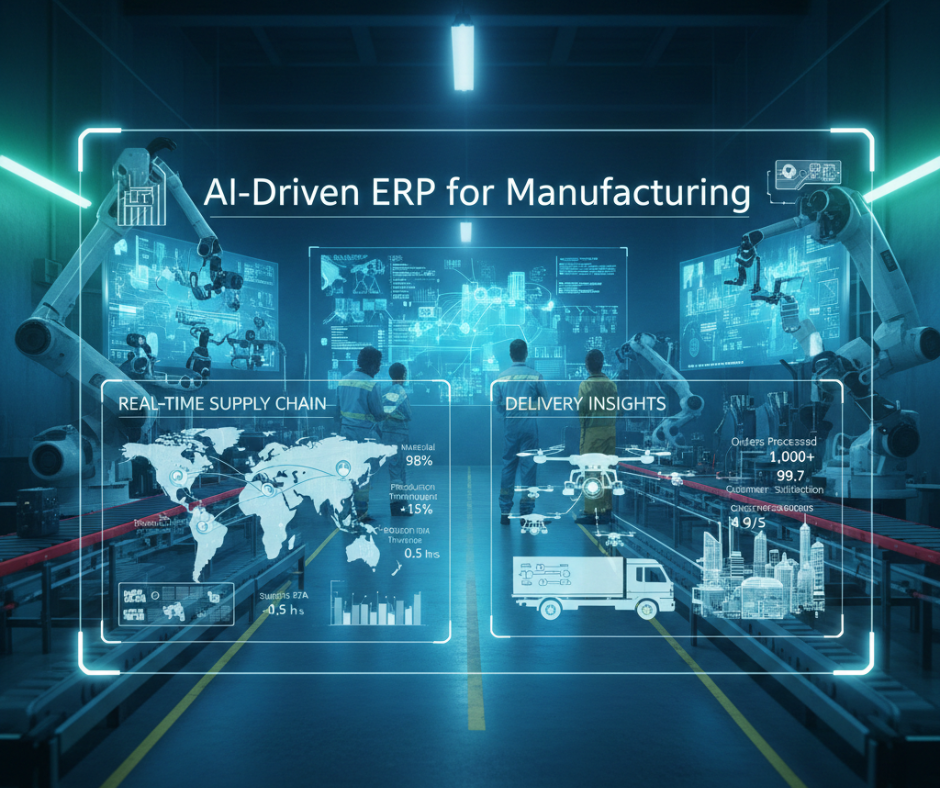

The manufacturing industry is undergoing a powerful digital transformation. Rising customer expectations, global supply chain disruptions, cost pressures, and the demand for faster delivery have pushed manufacturers to rethink how they manage operations. At the center of this transformation is AI-driven ERP (Enterprise Resource Planning)—a smarter, data-driven system that provides real-time visibility from supply chain sourcing to final delivery.

Traditional ERP systems are no longer enough. Today’s manufacturers need intelligent platforms that can analyze data, predict outcomes, and automate decisions. This is where AI-powered ERP systems are redefining efficiency, agility, and growth.

What Is an AI-Driven ERP System in Manufacturing?

An AI-driven ERP system integrates artificial intelligence, machine learning, and real-time analytics into core manufacturing operations. Unlike legacy ERP software that only records transactions, AI ERP systems actively analyze data and provide actionable insights.

These systems connect key manufacturing functions, including:

- Supply chain and procurement

- Production planning and scheduling

- Inventory and warehouse management

- Quality control

- Logistics and delivery tracking

- Financial forecasting

By using AI, manufacturers gain predictive intelligence rather than reactive reporting.

Real-Time Supply Chain Visibility

One of the biggest challenges manufacturers face is limited visibility into their supply chain. AI-driven ERP systems solve this by providing real-time insights across suppliers, warehouses, and production lines.

Key benefits include:

- Live tracking of raw material availability

- Automated supplier performance analysis

- Early alerts for supply disruptions

- Smarter vendor selection using historical data

With AI-powered insights, manufacturers can respond to supply chain issues before they impact production.

Intelligent Demand Forecasting and Production Planning

AI ERP systems analyze historical sales data, market trends, seasonality, and external factors to deliver accurate demand forecasts. This allows manufacturers to:

- Avoid overproduction or stock shortages

- Optimize production schedules

- Align procurement with actual demand

- Reduce waste and operational costs

Machine learning models continuously improve predictions as new data is introduced.

Smart Inventory Management

Inventory mismanagement leads to increased costs and delayed deliveries. AI-driven ERP systems maintain optimal inventory levels by:

- Predicting stock requirements

- Automating reordering processes

- Identifying slow-moving or obsolete stock

- Balancing warehouse distribution

This ensures materials are available when needed—without excess capital tied up in inventory.

Predictive Maintenance for Manufacturing Equipment

Unplanned downtime can significantly impact productivity and revenue. AI ERP systems use sensor data and historical maintenance records to:

- Predict equipment failures

- Schedule maintenance proactively

- Reduce downtime and repair costs

- Extend machinery lifespan

Predictive maintenance enables manufacturers to keep production running smoothly and efficiently.

Quality Control and Compliance Automation

Maintaining consistent product quality is essential in manufacturing. AI-driven ERP systems enhance quality control by:

- Detecting defects using data patterns

- Monitoring compliance with industry standards

- Automating inspection workflows

- Reducing manual errors

Real-time alerts help teams address quality issues before they escalate.

End-to-End Delivery and Logistics Insights

From factory floor to customer doorstep, AI ERP systems provide complete delivery visibility. Manufacturers can:

- Track shipments in real time

- Optimize logistics routes

- Predict delivery delays

- Improve on-time delivery rates

AI-powered insights help build stronger customer trust and satisfaction.

Data-Driven Decision Making Across Departments

AI-driven ERP systems break down silos by creating a single source of truth across departments. Executives and managers gain:

- Real-time dashboards

- Predictive financial insights

- Scenario-based planning tools

- KPI-driven performance tracking

This enables faster, smarter, and more confident decision-making.

Scalability and Future-Ready Manufacturing

As manufacturing businesses grow, AI ERP systems scale effortlessly. Cloud-based AI ERP platforms allow manufacturers to:

- Add new facilities and suppliers

- Integrate IoT and smart factory technologies

- Support global operations

- Adapt quickly to market changes

This flexibility ensures long-term sustainability and competitiveness.

Security and Data Integrity

Modern AI ERP platforms include advanced security features such as:

- Role-based access control

- Encrypted data storage

- Real-time anomaly detection

- Automated compliance reporting

These safeguards protect sensitive manufacturing and supply chain data.

The Future of Manufacturing ERP Is AI-Powered

The future of manufacturing lies in intelligent, autonomous systems. AI-driven ERP solutions are evolving toward:

- Self-optimizing production lines

- Autonomous supply chain planning

- Real-time collaboration with AI agents

- Predictive risk management

Manufacturers who adopt AI ERP today will lead the industry tomorrow.

Conclusion

AI-driven ERP systems are transforming manufacturing by delivering real-time insights from supply chain sourcing to final delivery. By combining automation, predictive analytics, and intelligent decision-making, these platforms empower manufacturers to reduce costs, improve efficiency, and meet customer demands with confidence.

Leave a Reply